SMART FUEL & FLEET™ CLEAN FUEL SYSTEM

Environmentally Friendly, High Performance Fuel Processing System

THE PROBLEM: Financing Infrastructure

School operational expenses increase annually while funding to cover those costs is become more scarce and hard to acquire. When budget increases are approved, the priority for use of funds is, rightfully so, targeted to the education and well-being of the student population.

Bus fleet upgrades and fueling infrastructure remediation costs are often deferred to the point of neglect. These costs can often reach into the millions of dollars and are considered capital equipment. Deferring infrastructure up-grades often

ultimately ends up costing the school district more money over the long run than if they had strategically upgraded their fueling infrastructure.

“I have been with fleet management services for more than 30 years and fuel sludge, algae, and contamination have always been a concern until we switched to HPCD. After 2 years of using HPCD, we observed a 10.7% reduction in fuel consumption.”

Darryl Syler | City of Dublin

Fleet Manager | Customer Since 2011

OUR PROVEN SOLUTION

HPCD has been proven to reduce fuel and operational costs for bus fleets by our long-term customers. These savings have allowed those districts to free up budgetary funding for other priority projects. Our on-site fuel-processing and storage systems further increase long term operational spending through multiple mechanisms including:

• A partnership program with KeyBank, a financing partner, allows school districts to lease the upgrades with operational capital while transferring ownership at the end of the lease

• Fleet annual maintenance costs have been demonstrated by customers to be significantly reduced due to the cleaner burning HPCD

• Increased fleet operational efficiency, documented by customers to exceed 10%, provides an immediate cost savings to the district

• Useful life extension of vehicles in the fleet defers unnecessary vehicle upgrade purchases or lease execution

• Our systems double walled container design significantly reduces liability costs for fuel on-site contamination and remediation costs

• Replacement tank and pump upgrades, a necessary requirement, offer no tangible cost savings or benefits when compared HPCD processing systems

• Break even costs of projects often occurs in less than 5 years with lease programs available in 10 to 20 year packages

• Our systems can be configured and installed in the manner that most benefits our customer, including staged integration and upgrade.

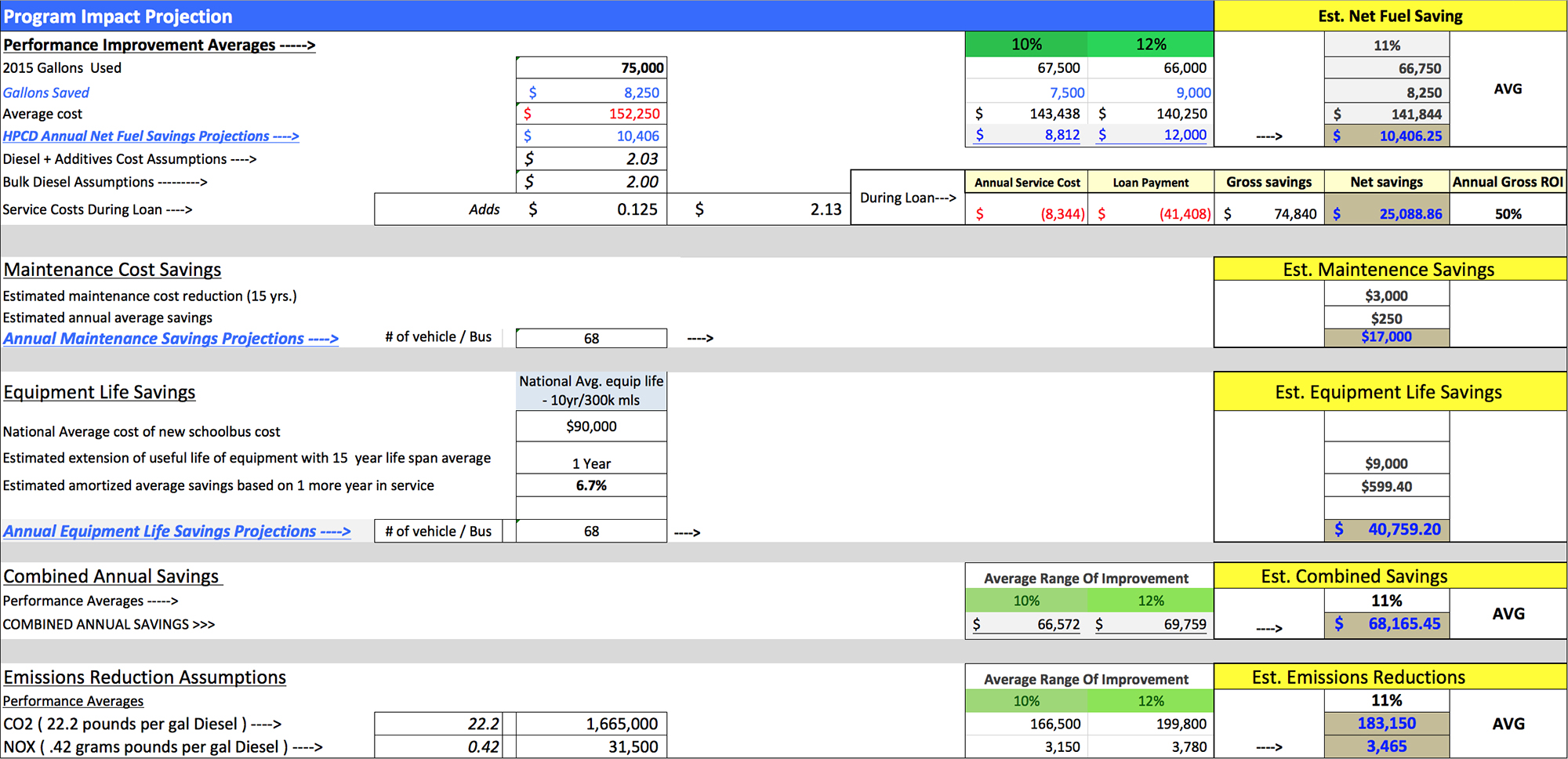

The below ROI shows a typical fleet of 70 buses, using an average of 75,000 gallons of diesel fuel annually.

Many “environmentally-friendly” fuel solutions are not self-sustaining and require either Government subsidies or premium cost, but HPCD™ actually pays for itself. The boxes below illustrate average fuel, maintenance savings, along with emission reductions based on the information gathered from your fleet and data collected from field studies on similar field types and conditions.

• ($8,344) Annual Service Contract (7yr)

• ($41,408) Equipment Loan (7yr)

• $10,406 Net Fuel Savings

• $6,675 HPCD Reduced Cost

• $17,000 In Annual Maintenance Cost Reductions

• $40,759 In Annual Equipment Life Savings

• $25,088 Total Net Annual Savings

• 183,150 Pounds Of CO2 Reduced Annually

• 3,465 Pounds Of Nox Reduced Annually